“Seawalls guard against coastal erosion, but cracks or fissures in the caps can lead to deterioration. Timely repairs are crucial for effective protection.”

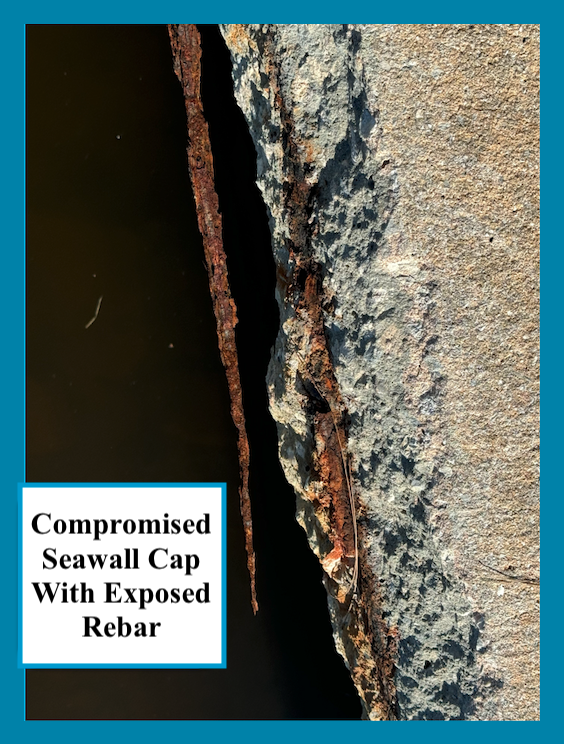

Seawall caps and concrete slabs are often subjected to premature deterioration and failure as a result of the extreme corrosive conditions to which they are exposed.

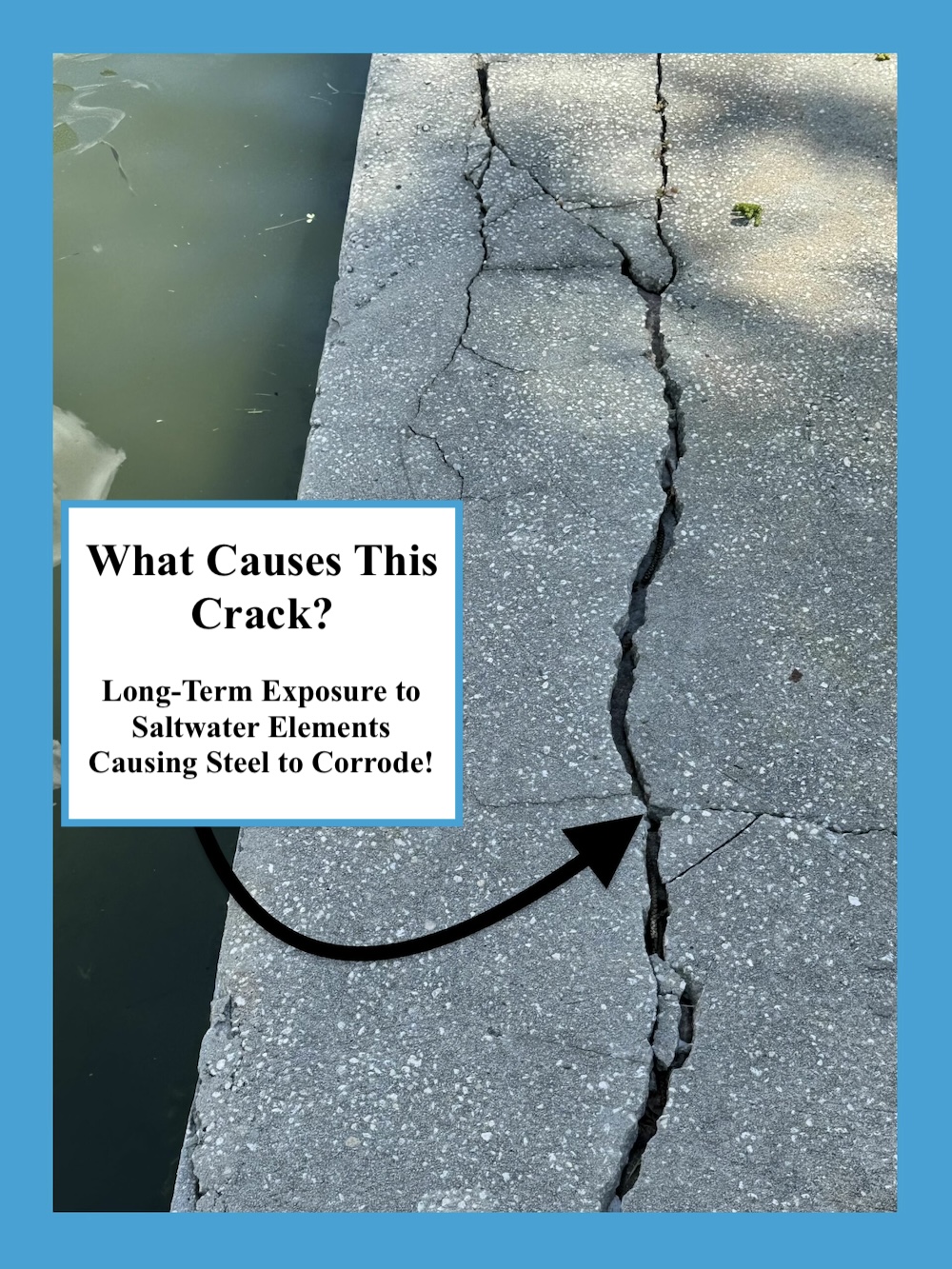

Horizontal cracks in seawall caps frequently indicate an underlying issue that demands prompt intervention. These cracks often arise due to various invisible forces being applied to the seawall structure. Forces such as, hydrostatic pressure exerted from behind the seawall structure can lead to tremendous stress on the structure. The saltwater intrusion into concrete attacks the reinforcing steel within the seawall cap and structural slabs.

Once the reinforcing steel (rebar) is exposed, this compromises the structural integrity of the seawall. If left unaddressed, these conditions can cause fracturing and splitting potentially leading to an exceptional stress on the seawall.

Frequently, a diagonal or vertical crack in your seawall foundation cap is the result of settling in the concrete seawall slabs and is quite common in seawall construction. Concrete shrinks while it cures, these cracks are termed shrinkage cracks. They usually run vertically or diagonally and are often positioned in the top section of walls. Shrinkage cracks are typically 1/8 in wide.

Be aware that concrete does in fact expand and contract, especially during hot summer months and when Florida’s afternoon thundershowers reduce the temperature on the concrete, it moves dramatically. If the crack is located closer to an edge or corner and is wider than 1/2 in, it is probably not due to shrinkage but indicates a more serious seawall foundation issue.

Engaging in predictive maintenance can help identify and address these issues early, while evaluating your options can guide you to effective repair strategies and solutions.

When a crack in your seawall is wide enough to fit a nickel, it’s a sign of a potential foundation issue that requires structural repairs. One effective method for addressing such cracks is epoxy injection, a sophisticated technique that rapidly restores the integrity of the concrete. This process involves injecting epoxy into the crack, effectively welding it back together and regaining the original strength and load-bearing capacity of the seawall. The epoxy not only repairs the crack but also enhances the seawall’s resistance to water, chemicals, debris, and other contaminants. Suitable for cracks as narrow as 0.002 inches, the epoxy injection procedure includes creating an entry point, sealing exposed surfaces, and injecting the epoxy under low pressure.

Pressure grouting is a specialized technique used to repair cracks in seawalls, particularly when conventional methods are insufficient. This method involves injecting a grout material under pressure to fill and seal cracks, restoring the integrity of the seawall structure.

Why Epoxy Grouting?

Seawalls are exposed to harsh environmental conditions, which can lead to the development of cracks. Epoxy pressure grouting is especially effective for:

Enhanced Durability: Reinforces the seawall by filling cracks and preventing further deterioration.

Water Resistance: Seals the cracks to prevent water infiltration, which can lead to additional damage.

Structural Integrity: Restores the structural load-bearing capacity of the seawall, crucial for maintaining its effectiveness.

Rather than demolishing your seawall, our state-of-the-art repair methods strengthen and extend its lifespan for decades. This cost-effective solution minimizes disruption and avoids the expense of full replacement. Utilizing advanced techniques like epoxy for predictive maintenance and targeted grout injections for optimal solutions, we offer customized strategies to enhance your seawall’s durability.

Contact our experts today for a free evaluation and see how you can save while preserving your seawall.

Questions about your seawall repair options? Contact our office today for a FREE estimate. We welcome the opportunity to review your seawall needs and earn your business!

(239) 284-6830